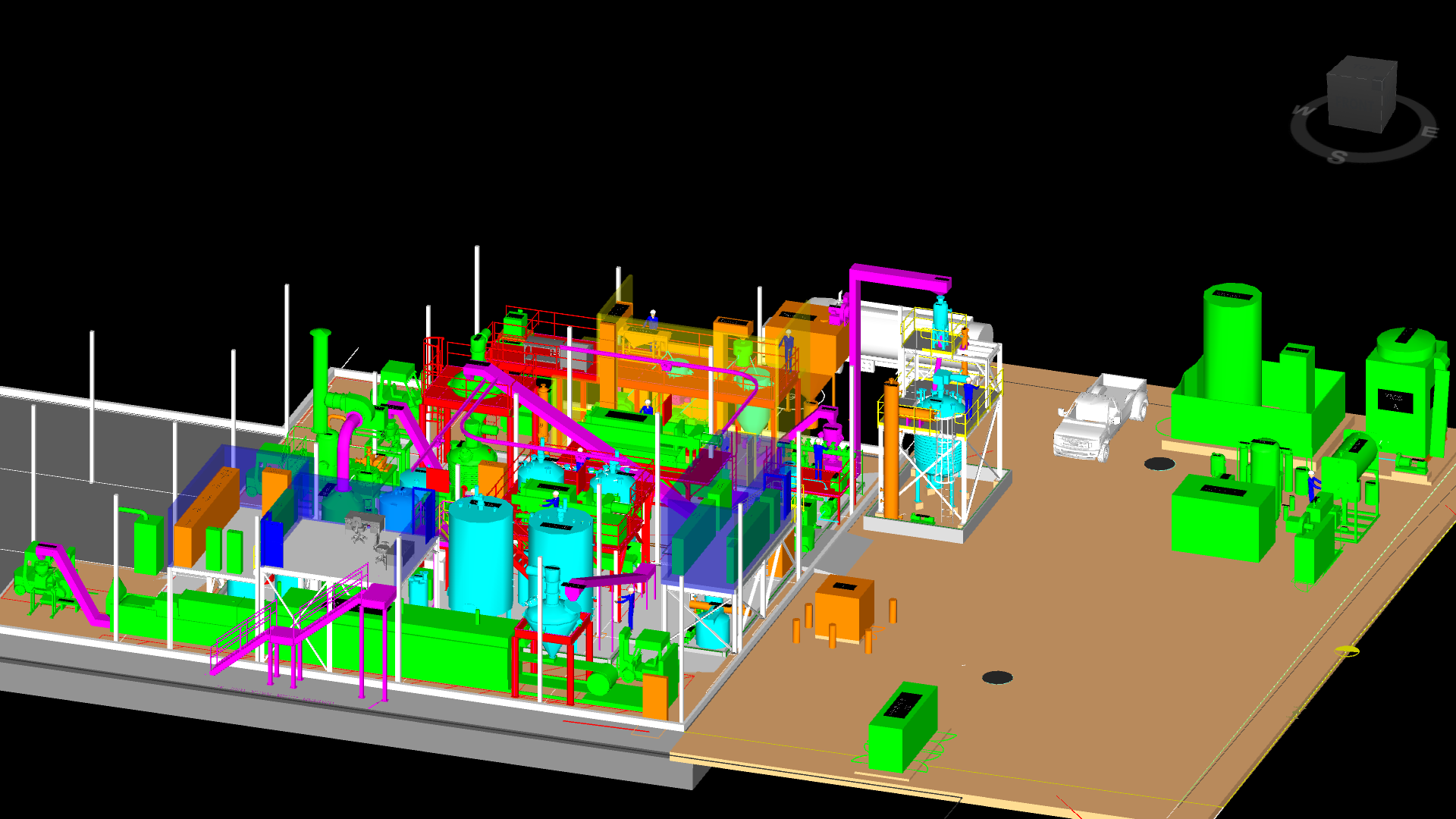

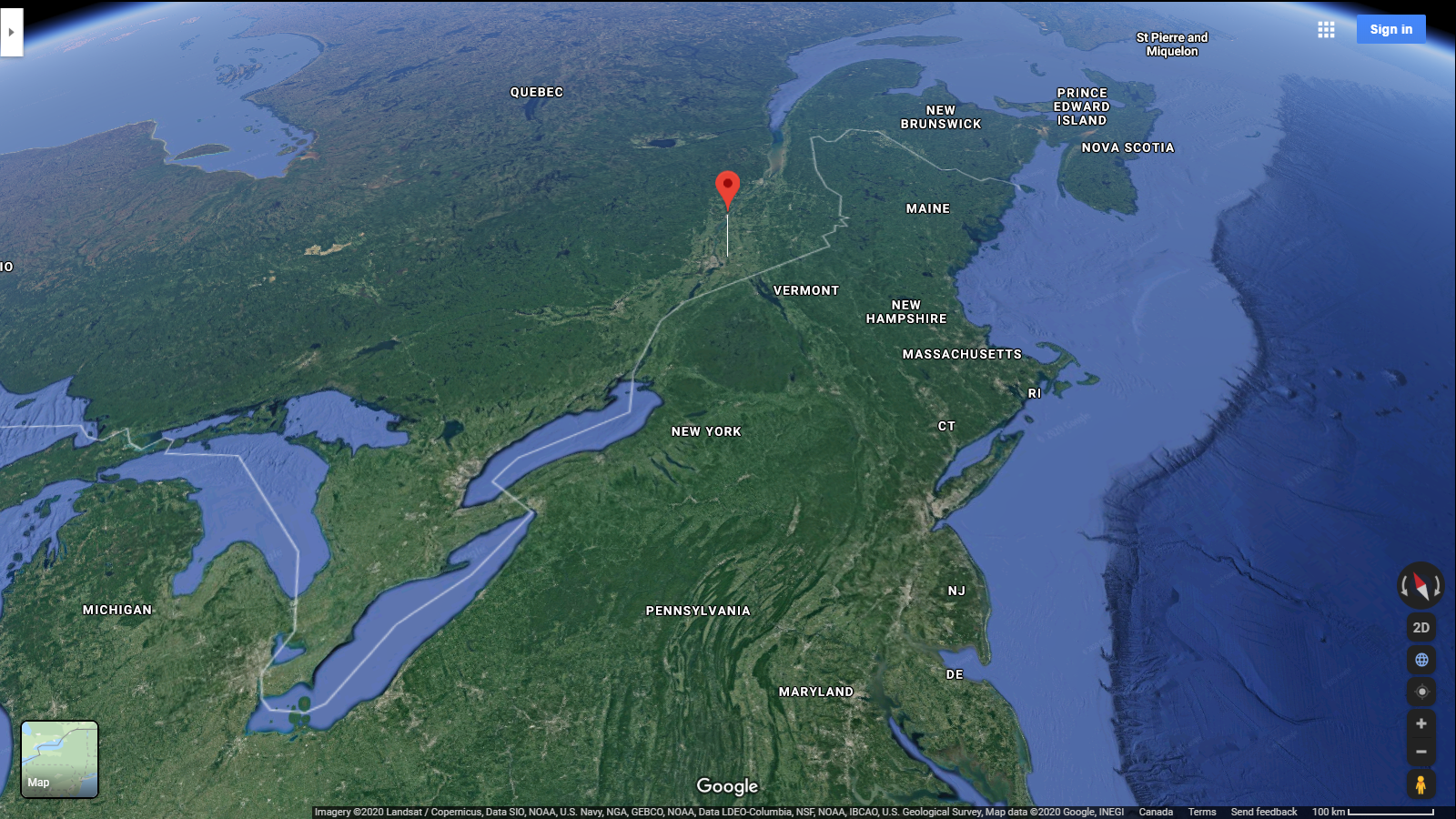

“Geomega’s chemical processing team has proven once again its skill to utilize its expertise with evolving market conditions. I am proud of our team that shows flexibility, motivation and creativity, especially during a difficult situation like we see globally today. Geomega can assure its shareholders that these modifications to the pilot plant will in no way impede the progress of building the much larger demonstration plant located in nearby St. Bruno, Quebec. Geomega strives to become Canada’s first rare earth oxide producer, using recycled magnet waste, making Canada one of the few countries outside of Asia to be able to do so. Geomega has continued to advance even under recent difficult social distancing measures and is progressing successfully in the engineering work with Hatch. Upon engineering being completed, ordering the long lead items for the facility will be a priority. Geomega had recently secured project debt financing of $1.72M from the Quebec Government this February (see news release dated February 7, 2020) which has effectively fulfilled the required capital to complete construction of the Demonstration Plant. Geomega, in conjunction with the Quebec Government, has a very clear objective to establish Quebec as a hub for a clean technology and sustainable rare earths refining industry, self reliant and not dependant on other countries for key materials. In light of recent events and supply shortages, as highlighted by reported delays in medical ventilators construction due to lack of permanent magnets (see full article here), this has never been more critical. Geomega looks forward to further engagement with end users and Governments on rare earths recycling and establishing a sustainable supply chain based right here in Quebec, Canada.” Commented Kiril Mugerman, President & CEO of Geomega.