Swarf from permanet magnets, Robert Baylis & Adamas Intelligence tweets

Learn about our target markets on social media.

Robert Baylis on Twitter

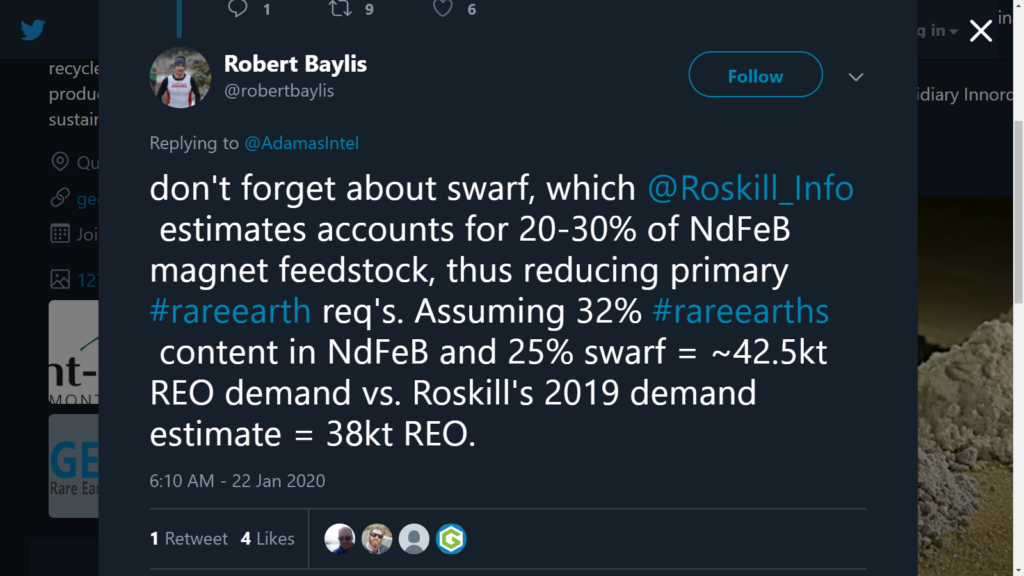

@AdamasIntel don’t forget about swarf, which @Roskill_Info estimates accounts for 20-30% of NdFeB magnet feedstock, thus reducing primary #rareearth req’s. Assuming 32% #rareearths content in NdFeB and 25% swarf = ~42.5kt REO demand vs. Roskill’s 2019 demand estimate = 38kt REO.

When Robert Baylis tweets that Roskill estimates “20-30% of NdFeB magnet feedstock” comes from swarf today, we retweeted it. That’s a lot of recycling.

Swarf refers to “fine chips or filings of stone, metal, or other material produced by a machining operation.” (Google). Read the discussion between Robert Baylis and Adamas Intelligence on twitter here.

“@AdamasIntel don’t forget about swarf, which @Roskill_Info estimates accounts for 20-30% of NdFeB magnet feedstock, thus reducing primary #rareearth req’s. Assuming 32% #rareearths content in NdFeB and 25% swarf = ~42.5kt REO demand vs. Roskill’s 2019 demand estimate = 38kt REO.” Adam Baylis, January 22nd 2020.

These numbers are relevant to our target market.

Note that Robert Baylis mentions “32% rare earths content in NdFeB” for swarf from permanent magnet manufacturing in his tweet. That number is in-line with our guidance on the expected grade of our feed material.

As our CEO said to Steve Darling at Cambridge House 25th annual VRIC,

“We are starting with the best feed out there, which is the magnet.” Kiril Mugerman

How much metal is cut away during the machining process? How much swarf is produced by different magnet manufacturers around the world? How much material can we expect from that waste stream as a source of feed for our recycling?

Again, quoting Kiril in his recent appearance with Proactive Investors,

Read on for more information from Adamas Intelligence, who notes that China is “reliant” on rare earths imports. Adamas tweets, Chinese rare earth production volumes are “far more than China can yield with domestic #rareearth supplies alone.” Recycling swarf is one source for magnet material in China.

Is recycling swarf from permanent magnet manufacturing an important factor for the global rare earths markets?

Note, this interview with Kiril was recorded January 20th 2020 at Cambridge House’s 25th annual VRIC. These tweets between Roskill and Adamas were from January 22nd. No sooner did Kiril say, “they do recycle in China… Nobody talks about it.” than we start seeing tweets about it from the likes of Adamas Intelligence and Adam Baylis! What would Clint Cox say?

Watch for more.